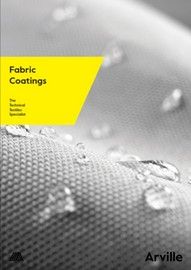

Coated Fabrics

Which coating is the best for your end application?

Arville are specialists in the coating of technical textiles with access to a wide range of coating compounds and chemical formulations which, when applied to fabrics, can be used to give a much broader, enhanced set of operating characteristics.

Our coated fabrics have a wide range of applications and are designed to withstand some of the most challenging end uses.

Coated Fabrics Engineered for High Performance

We manufacture bespoke coated fabrics for a wide range of industrial purposes, as we also have the capability to weave the base textiles, this allows us to control the specification throughout, making a higher-quality product more easily.

The versatility of our dedicated coating lines means that we can also offer commission coating services to customers who prefer to free issue their own fabrics.

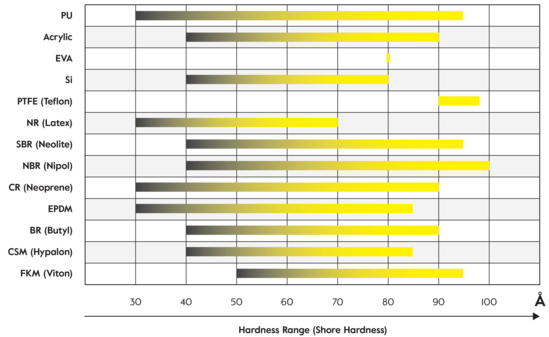

In the below table, you can see the various hardness ranges (measured in Shore Hardness) of the most used coating compounds we work with, ranging from PU and Acrylic to more specialist coatings, such as Viton and Neoprene.

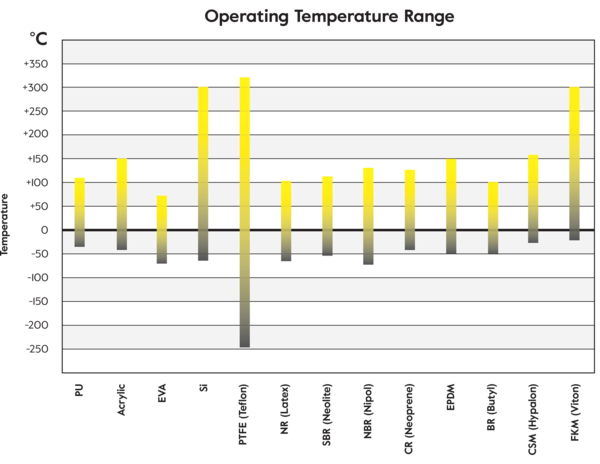

The following table shows the operating temperature range (in Celsius) of the same selection of coating compounds which can be supplied as single-sided, double-sided, differentially coated or even sandwich layered (combined) between different base textiles.

Leading Coated Fabrics Manufacturers

Arville actively works with some of the most scientifically advanced organisations in the world, who operate at the forefront of material science and technology to ensure that our technical team has access to the latest developments in a wide range of rubbers, polymers and chemical solutions, including Polyurethane, Acrylic, EVA, Silicone, PTFE, Natural latex, Styrene, Nipol, Neoprene, EPDM, Butyl, Hypalon and Viton.

When formulated into coating compounds and applied to fabrics, they are designed to add a wide range of enhancements such as extra strength, durability, temperature resistance, barrier properties, water-proofing, and resistance to aggressive substances such as solvents, acids, alkalis, fossil fuels and many more.

Coated Fabrics Enhanced Characteristics

Our technical team have extensive experience in creating bespoke coated fabrics that are designed to meet a specific challenge. The table below shows a range of the characteristics that can be achieved through textile coatings, in various combinations and to various degrees.

|

Fuel resistance |  |

Heat resistance |

|

Ozone resistance |  |

Gas permeability |

|

UV resistance |  |

Gas barrier |

|

Improved tensile strength |  |

Weather resistance |

|

Good stretch |  |

High/low friction |

|

Abrasion resistance |  |

Tear resistance |

|

Chemical resistance |  |

Increased rigidity |

|

Oil resistance |  |

Acid resistance |

|

Flame resistance |  |

Alkali resistance |

|

Water repellancy/resistance |  |

Solvent resistance |

Related Resources

Want to know more? Here are some technical brochures that may be of interest, or if you would like to see our full range of PDF downloads then please go to our Technical Library