Our Weaving Processes

Yarn Twisting

Operating our own in-house ring twisting machinery provides us with the flexibility to twist yarn to the specific twist level that is optimal for a particular fabric specification

Electronic drive control provides high levels of accuracy of twist levels and consistent performance. Our data banks keep a library of stored customer settings and are able to recall pre-set yarn styles, ensuring accurate repeatability and consistency throughout

Additional specialist twisting machinery is used that allows us to produce hybrid yarns using multifilament, spun and monofilament yarns of varying counts to produce a bespoke product. This is particularly useful for customers who require the introduction of anti-static, conductive or reinforcement yarns

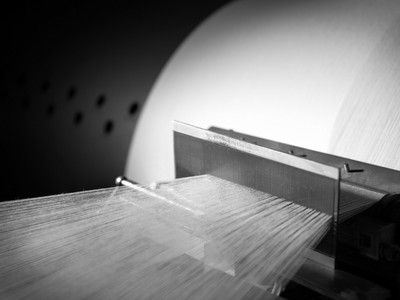

Warping

Precision sectional warping machinery gives us full control over the preparation of weaving beams. Control over the warping process allows us to rapidly respond to customer needs and to prepare complex warps with highly accurate section alignment, yarn control and tension levels

We have the ability to handle a wide variety of both multifilament and spun yarn types, including high performance technical yarns such as para-aramids and difficult to handle yarns such as UHMWPE (ultra high molecular weight polyethylene)

Sectional warping allows for fast, consistent and controlled loom set-up. In-house warping machinery allows us to be more responsive to our customers’ needs and is ideal for producing both long warps for full-scale production runs and shorter warp lengths for bespoke runs and development work

Weaving

We have an extensive fleet of Dornier rapier looms capable of weaving fabric up to 340cm wide and fabric weights from 25gsm up to 3,000gsm. In addition, we operate a fleet of shuttle looms capable of weaving tubular fabrics at widths up to 220cm wide

A number of our looms are allocated to ongoing development work for our customers, allowing us to offer flexible manufacturing and full-width production of short run-lengths

We produce flat, multi-layer and tubular weaves and over the years have worked with our customers to develop many complex weave patterns and constructions designed to impart specific performance characteristics. We have an extensive database of fabrics and their technical attributes and would be delighted to work with you to tailor a fabric to suit your needs

Weave type |

Widths (cm) |

Weight (g/m²) |

||

Min |

Max |

Min |

Max |

|

| Flat | 65 | 340 | 25 | 1,500 |

| Multi-layer | 120 | 260 | 25 | 3,000 |

| Tubular | 65 | 220 | 25 | 1,500 |

| Plain | 65 | 340 | 25 | 1,500 |

| Twill | 65 | 340 | 25 | 1,500 |

| Broken twill | 65 | 340 | 25 | 1,500 |

| Satin | 65 | 340 | 25 | 1,500 |

| Matt | 65 | 340 | 25 | 1,500 |

| Mock leno | 65 | 340 | 25 | 1,500 |

| Bespoke | 65 | 340 | 25 | 3,000 |

Finishing

To deliver specific performance characteristics or to prepare the fabric for use in further industrial processes we can apply a range of bespoke finishing processes to fabrics

Our in-house finishing capabilities are extensive, allowing us to develop for our customers an end product of high quality fabric, engineered to have performance characteristics that exactly meets their requirements

|

Scouring |  |

Multi-point slitting |  |

Singeing |

|

Heat-setting |  |

Priming treatments |  |

Fire retardant treatments |

|

Release finishes |  |

Water repellancy treatments |  |

Bias cutting |

Related Resources

Want to know more? Here are some technical brochures that may be of interest, or if you would like to see our full range of PDF downloads then please go to our Technical Library