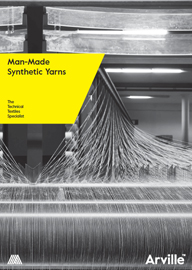

Man-Made Synthetic Yarns

Today’s commonly used man-made fibres are the result of developments in material science to improve on naturally occurring plant fibres.

They are generally formed by extruding materials (often originating from petrochemicals) through spinnerets into air and water to form a thread.

Man-made fibres are generally more durable than most natural fibres and offer a range of desirable characteristics which often make them suited to high performance and technical end applications.

Polyester (polyethylene terephthalate)

Polyester is a category of polymers that contain the ester functional group within their main chain of molecules.

In the form of a yarn there are a whole host of derivatives making polyester a versatile and cost-effective yarn suitable for weaving into fabric for a wide range of end applications

Variants: Multifilament, monofilament, spun staple, textured, high tenacity, medium tenacity, low-shrink, high-shrink

Characteristics: Strength, abrasion resistance, resistant to stretching and shrinking, resistant to most chemicals

Typical End Uses: Lightweight conveyor & process belting, sail cloth, general fabrics, reinforcement of mechanical rubber goods (diaphragms, hoses, etc.)

Polypropylene (PP)

Polypropylene is a termoplastic polymer used in a wide variety of general applications. It is a derivative of the monomer propylene which is polymerised into a series of long-chain molecules.

When spun into fibres it produces a lightweight yarn which is tough and flexible, having a smooth, ‘low energy’ surface.

Variants: Continuous filament, monofilament, spun staple, low-shrink, medium tenacity, high tenacity

Characteristics: Excellent chemical resistance to acids and alkalis, cost-effective, thermally bondable, stain and soil resistant, high strength, low heat resistance

Typical End Uses: Filtration media, bulk lifting bags, straps, medical equipment, rubber process liners

Modacrylic/Acrylic (poly methyl methacrylate)

Modacrylic is a synthetic copolymer made from modified acrylic fibres.

Acrylics and modacrylics differ in the proportion of acrylonitrile content – modacryclic has a reduced composition of approx 35-40% acrylonitrile bulked out with other polymers whereas true acrylic consists of 100% acrylonitrile.

Modacrylics are soft, strong and dimensionally stable, having properties similar to acrylic. However, modacrylics are flame retardant and do not combust.

Variants: Spun staple

Characteristics: UV stability, flame retardant, self-extinguishing, durability, arc-flash protection, dimensional stability, high elastic recovery

Typical End Uses: Shades, screens, military seating (covers), protective clothing

Nylon (polyamide)

Nylon is a generic designation for a family of semi-aromatic polyamides. Nylon poymers can be mixed with a wide variety of additives to acheive many different property variations.

In yarn form, Nylon 6 and Nylon 6.6 are commonly used in technical textile applications.

The majority of nylons tend to be semi-crystalline and are generally very tough materials with good thermal properties, strength and chemcial resistance

Variants: Continuous filament, monofilament, high tenacity, medium tenacity, Nylon 6, Nylon 6.6, texturised, low-shrink, high-shrink

Characteristics: High strength, extensibility, excellent abrasion resistance, melts instead of burning, chemical resistance, permeability, printability, UV resistance

Typical End Uses: Rubber reinforcements (hoses, diaphragms, sheets), high performance inflatables

Technical Specifications

You can compare some of our most commonly used technical yarns in the table below. If you have any further queries, or are interested in a yarn not listed, please don't hesitate to contact us.

Yarn Type |

Yarn Count |

Twist (tpm) |

||

| Min | Max | Min | Max | |

| Polyester | 50 dtex | 6,000 dtex | Flat | 700 |

| Polypropylene | 210 Denier | 2,200 Denier | Flat | 250 |

| Modacrylic/Acrylic | Ne 40/2 | Ne 15/2 | 200 | 400 |

| Nylon | 22 dtex | 6,000 dtex | Flat | 700 |

Related Resources

Want to know more? Here are some technical brochures that may be of interest, or if you would like to see our full range of PDF downloads then please go to our Technical Library